Manufacturing Work Management

With the shift to remote work, disruptions in the supply chain, and volatile demand levels technology has become more important than ever. Manufacturing companies are looking for resiliency, efficiency, and visibility. Now is the time to invest in bringing your outdated process up to speed with solutions that can be implemented quickly with a clear ROI. Microsoft 365 applications offers you the tools to bring stability to an ever-changing industry while remaining focused on your bottom line.

Manufacturing Work Management

With the shift to remote work, disruptions in the supply chain, and volatile demand levels technology has become more important than ever. Manufacturing companies are looking for resiliency, efficiency, and visibility. Now is the time to invest in bringing your outdated process up to speed with solutions that can be implemented quickly with a clear ROI. Microsoft 365 applications offers you the tools to bring stability to an ever-changing industry while remaining focused on your bottom line.

Manufacturing Challenges & Solutions

Outdated Technology

Disparate systems prevent on-time delivery and cause replicated processes. Multiple systems and processes reduce productivity and visibility. First-line workers rely on slow and error-prone manual processes have an increased risk of errors and worker safety.Factory of the Future

Minimize human error and make data immediately available in real time by transforming workflows, inspections, and approvals with digital applications. Empower employees to do their best work with tailored digital solutions that feature modern interfaces, real-time insights, and new collaborative capabilities. Maximize worker safety and reduce risk by adopting exciting new technologies today.

Lack of Data and Insights

Lack of visibility can result in inability to adapt to evolving demand and behavior, as well as delivering unique experiences for the end user. Inefficiencies hurt the bottom line and identify bottlenecks, causing costly delays.Proactive Data Driven Insights

Increase visibility into the value chain to identify emerging needs and eliminate bottlenecks. Work effectively with partners and suppliers to minimize time and cost while maximizing value to the customer. Get the visibility you need to make proactive data driven decisions.

Skilled Labor Shortage

Manufacturing faces a crisis matching talent to business needs and the perception that it is repetitive work with little opportunity for advancement. Not only is there an overall shortage of workers, but many lack the skills necessary for modern manufacturing environments.Attract & Retain Skilled Employees

With a comprehensive approach that encompasses expanded hiring practices using prebuilt cloud machines, enhanced training using modern technology like mixed reality, and an engaging workplace. Automate mundane tasks to liberate creativity and create a more enjoyable work environment. Implement enterprise-wide digital collaboration environments for effective team operations.

Microsoft 365 Empowers Users to do More

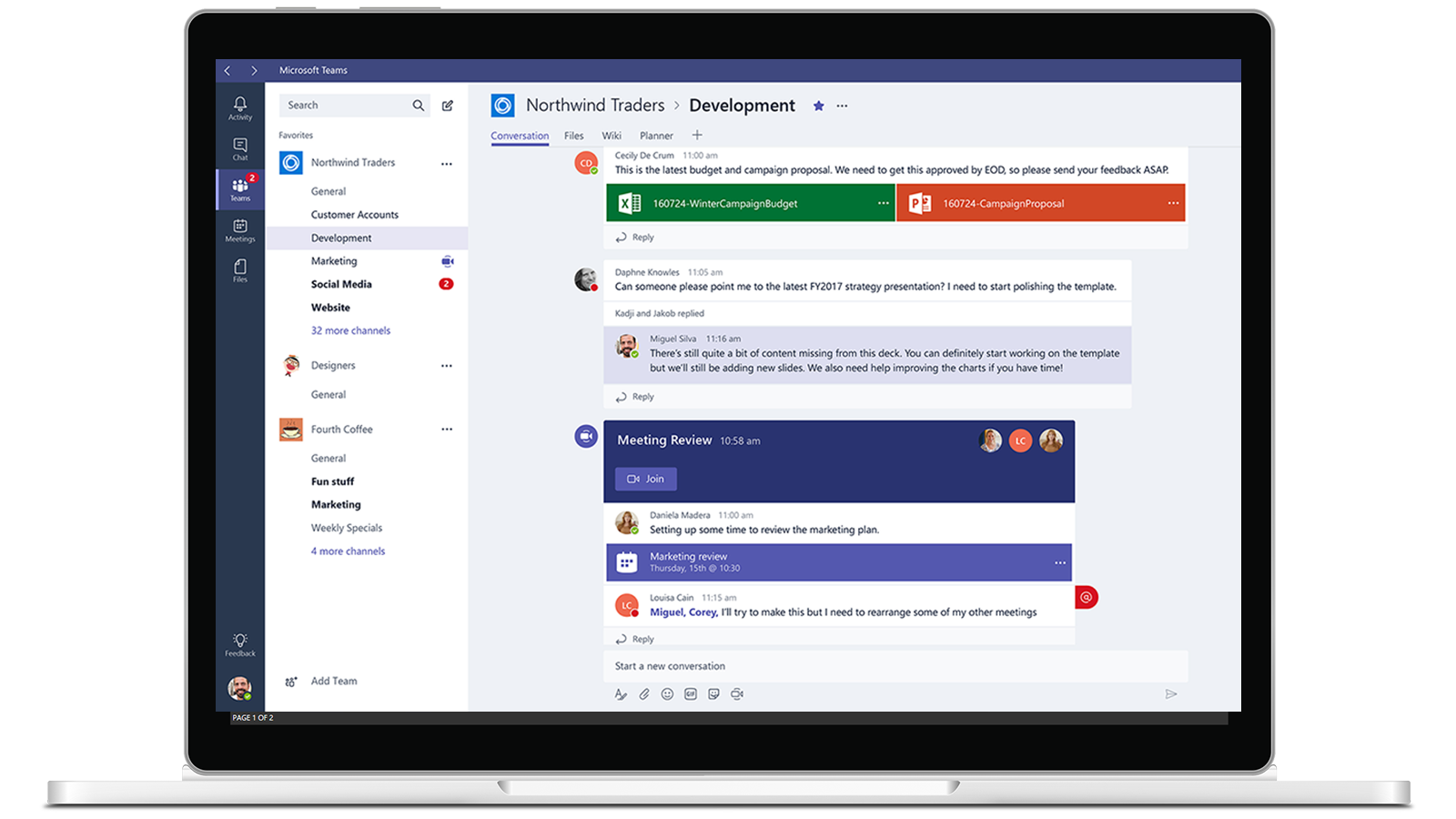

Teams

Empower your workforce across every function with Teams, your hub for teamwork and collaboration. Respond in real-time to time-sensitive events like production stoppages through Teams using embedded apps allowing users to have all the information they need at their fingertips – all in one location. Teams Chat and embedded apps give employees the ability to report concerns that may cause delays, quality issues, equipment malfunctions, or material shortages. Working together, no matter where you are, has never been easier.

Project

Microsoft Project offers a powerful, easy to use work management tool enabling anyone in your organization to track and manage projects of all sizes for complete organizational visibility. Deliver profitable projects on time and on budget, by creating interactive dashboards with detail drill down capabilities. Easily plan with the power of dynamic scheduling, track effort needed, project duration, and team members allocation. Manage agile projects using simple, visual task boards that support Scrum, Kanban, or hybrid methodologies.

IoT & AI

Create the factory of the future by augmenting industrial automation with Internet of Things (IoT), cloud-based computing, artificial intelligence (AI), and mixed reality to drive your business to new levels of efficiency and innovation. Enhance manufacturing and employee productivity by combining IoT-enabled machines and AI enhanced applications with your workforce. Add cloud intelligence to factory solutions from our comprehensive ecosystem.

Power Automate

Create powerful workflows to streamline repetitive tasks, minimize human error, replace traditional paper processes, and make data immediately available using Power Automate. Connect to hundreds of popular Microsoft and third-party apps and services. Realize on average 38% time savings for your teams, allowing more time to do work that really matters. Increase employee satisfaction and happiness by automating the mundane, rule-based tasks.

Power BI

With an easy to use platform and rich visualizations and dashboards Power BI empowers all levels of your company, from executives to factory workers. By connecting your most used applications you can see all your data in one place giving you the confidence to make informed, data-driven decisions and proactive insights. Improve profitability and resiliency through increased visibility to identify developing needs, inventory management, and bottlenecks.

Power Apps

Create no and low-code custom apps with minimal investment to solve your manufacturing challenges. Empower first-line workers with apps that digitize manual processes, help them upskill efficiently, and provide critical risk management and safety information at the point of need. Boost collaboration with purpose-built solutions for research, design, engineering, and production teams that interact with connected product data in new and valuable ways that you never dreamed possible.

Manufacturing Challenges & Solutions

Outdated Technology

Disparate systems prevent on-time delivery and cause replicated processes. Multiple systems and processes reduce productivity and visibility. First-line workers rely on slow and error-prone manual processes have an increased risk of errors and worker safety.Factory of the Future

Minimize human error and make data immediately available in real time by transforming workflows, inspections, and approvals with digital applications. Empower employees to do their best work with tailored digital solutions that feature modern interfaces, real-time insights, and new collaborative capabilities. Maximize worker safety and reduce risk by adopting exciting new technologies today.

Lack of Data and Insights

Lack of visibility can result in inability to adapt to evolving demand and behavior, as well as delivering unique experiences for the end user. Inefficiencies hurt the bottom line and identify bottlenecks, causing costly delays.Proactive Data Driven Insights

Increase visibility into the value chain to identify emerging needs and eliminate bottlenecks. Work effectively with partners and suppliers to minimize time and cost while maximizing value to the customer. Get the visibility you need to make proactive data driven decisions.

Skilled Labor Shortage

Manufacturing faces a crisis matching talent to business needs and the perception that it is repetitive work with little opportunity for advancement. Not only is there an overall shortage of workers, but many lack the skills necessary for modern manufacturing environments.Attract & Retain Skilled Employees

With a comprehensive approach that encompasses expanded hiring practices using prebuilt cloud machines, enhanced training using modern technology like mixed reality, and an engaging workplace. Automate mundane tasks to liberate creativity and create a more enjoyable work environment. Implement enterprise-wide digital collaboration environments for effective team operations.

Microsoft 365 Empowers Users to do More

Teams

Empower your workforce across every function with Teams, your hub for teamwork and collaboration. Respond in real-time to time-sensitive events like production stoppages through Teams using embedded apps allowing users to have all the information they need at their fingertips – all in one location. Teams Chat and embedded apps give employees the ability to report concerns that may cause delays, quality issues, equipment malfunctions, or material shortages. Working together, no matter where you are, has never been easier.

Project

Microsoft Project offers a powerful, easy to use work management tool enabling anyone in your organization to track and manage projects of all sizes for complete organizational visibility. Deliver profitable projects on time and on budget, by creating interactive dashboards with detail drill down capabilities. Easily plan with the power of dynamic scheduling, track effort needed, project duration, and team members allocation. Manage agile projects using simple, visual task boards that support Scrum, Kanban, or hybrid methodologies.

IoT & AI

Create the factory of the future by augmenting industrial automation with Internet of Things (IoT), cloud-based computing, artificial intelligence (AI), and mixed reality to drive your business to new levels of efficiency and innovation. Enhance manufacturing and employee productivity by combining IoT-enabled machines and AI enhanced applications with your workforce. Add cloud intelligence to factory solutions from our comprehensive ecosystem.

Power Automate

Create powerful workflows to streamline repetitive tasks, minimize human error, replace traditional paper processes, and make data immediately available using Power Automate. Connect to hundreds of popular Microsoft and third-party apps and services. Realize on average 38% time savings for your teams, allowing more time to do work that really matters. Increase employee satisfaction and happiness by automating the mundane, rule-based tasks.

Power BI

With an easy to use platform and rich visualizations and dashboards Power BI empowers all levels of your company, from executives to factory workers. By connecting your most used applications you can see all your data in one place giving you the confidence to make informed, data-driven decisions and proactive insights. Improve profitability and resiliency through increased visibility to identify developing needs, inventory management, and bottlenecks.

Power Apps

Create no and low-code custom apps with minimal investment to solve your manufacturing challenges. Empower first-line workers with apps that digitize manual processes, help them upskill efficiently, and provide critical risk management and safety information at the point of need. Boost collaboration with purpose-built solutions for research, design, engineering, and production teams that interact with connected product data in new and valuable ways that you never dreamed possible.

PPM Works’ Data Visualization App for Manufacturing

Bring your data to life on your existing Visio diagrams by creating interactive visualizations of your current process drawings, manufacturing lines, or system architecture. This is a big win for your first line workers who will enjoy the user-friendly tablet interface. Save time, increase safety and respond in real time by putting technology to work for you and upgrading the tradition pen and paper methods.

PPM Works’ Data Visualization App for Manufacturing

Bring your data to life on your existing Visio diagrams by creating interactive visualizations of your current process drawings, manufacturing lines, or system architecture. This is a big win for your first line workers who will enjoy the user-friendly tablet interface. Save time, increase safety and respond in real time by putting technology to work for you and upgrading the tradition pen and paper methods.

Maximizing Efficiency is Key

20% increase in productivity can be achieved by adopting smart factory approaches through data and automation.

64% of first-line workers lack the technology tools they need—many of them rely on slow and error-prone manual processes.

Increase Resiliency Through Transformation

Transform your workforce

Give your people the tools they need to help business groups move from data to decisions in hours, not months. Equip them to analyze production, sales, and revenue data securely—by utilizing industry standard data security and access controls—while staying connected wherever they are.

Engage customers in new ways

Know your customers better. See their purchasing patterns, then provide personalized service with powerful insights from your marketing, sales, and service data. Use advanced analysis and AI to remotely monitor equipment and provide proactive, preventative maintenance.

Create more resilient supply chains

Discover actionable insights based on warehouse capacity usage, inventory levels, and delivery logistics to uncover bottlenecks in the supply chain. Improved visibility means you’re better positioned to plan for, and meet, future customer demand.

Build more agile factories

Quickly identify areas of operational efficiency in real time by analyzing costs, capacity, and output data to avoid delays across the manufacturing line. Visualize terabytes of data from equipment sensors, then use AI to predict hardware issues and prevent production disruptions.

Unlock innovation and deliver new services

Create new business opportunities by building a data culture—empowering every employee to access, collaborate on, and analyze data across your organization using self-service data connectors and custom visualization tools.

Maximizing Efficiency is Key

20% increase in productivity can be achieved by adopting smart factory approaches through data and automation.

64% of first-line workers lack the technology tools they need—many of them rely on slow and error-prone manual processes.

Increase Resiliency Through Transformation

Transform your workforce

Give your people the tools they need to help business groups move from data to decisions in hours, not months. Equip them to analyze production, sales, and revenue data securely—by utilizing industry standard data security and access controls—while staying connected wherever they are.

Engage customers in new ways

Know your customers better. See their purchasing patterns, then provide personalized service with powerful insights from your marketing, sales, and service data. Use advanced analysis and AI to remotely monitor equipment and provide proactive, preventative maintenance.

Create more resilient supply chains

Discover actionable insights based on warehouse capacity usage, inventory levels, and delivery logistics to uncover bottlenecks in the supply chain. Improved visibility means you’re better positioned to plan for, and meet, future customer demand.

Build more agile factories

Quickly identify areas of operational efficiency in real time by analyzing costs, capacity, and output data to avoid delays across the manufacturing line. Visualize terabytes of data from equipment sensors, then use AI to predict hardware issues and prevent production disruptions.

Unlock innovation and deliver new services

Create new business opportunities by building a data culture—empowering every employee to access, collaborate on, and analyze data across your organization using self-service data connectors and custom visualization tools.